Fitting Method of Barrier Parameters (transmission rate, permeability coefficient, diffusion coefficient and solution coefficient )

As we know, temperature affects barrier test of materials significantly. The fluctuation of temperature can lead to great changes of barrier property. To obtain accurate and scientific barrier data at a certain special temperature, the most common method is to perform practical test at this temperature. But in reality the usage temperature range of a test instrument generally cannot meet this requirement. So how can we get the barrier data at these temperatures accurately and scientifically? A fitting method of barrier parameters (transmission rate, permeability coefficient, diffusion coefficient and solution coefficient) will help us figure it out.

1. Fitting Method of Barrier Parameters

Fitting is a mathematic computational method used to get an approximation function of discrete data. The fitting method of barrier parameters, in brief, is a mathematic computational process, in which first a group of test data at accessible temperatures are obtained using a relative test instrument, then we can obtain barrier data of special temperatures through fitting arithmetic.

2. Arrhenius Law

The relations between permeability coefficient, diffusion coefficient, solution coefficient and temperature are all regulated by Arrhenius Law:

P=P0e-EP/RT

D=D0e-ED /RT

S=S0e-⊿ H/RT

P, D, S--- permeability coefficient, diffusion coefficient, solubility coefficient

P0, D0, S0 --- gas-solid constant depending on different gas-solid pairs

EP, ED, ⊿H--- permeability activation energy, diffusion activation energy, solution heat

R--- gas constant, 8.31441J/mol · K

T--- absolute temperature, K

For usual gases, with the rising of temperature the P, D and S increase i.e. the fluctuation of temperature obviously affects the test results.

3. Fitting Function of Labthink VAC-V1 for Barrier Parameters

Labthink has developed a new model of permeability test instrument: VAC-V1 Gas Permeability test instrument which has the function of barrier parameter fitting. Through tests by VAC-V1, more than 2 groups of test data of different temperatures can be obtained and then the user can use the fitting function of the instrument to get the gas transmission rate, permeability coefficient, diffusion coefficient and solubility coefficient. The more test data are tested the more accurate fitting results we can get. Since VAC-V1 has temperature self-control performance in the temperature range: room temperature ~ 50 °C , this makes the usage of fitting function of barrier parameters more easy and convenient.

Well, using VAC-V1,we got there test datas of a PC film 125μm thickness at different temperatures: 30 °C , 35 °C , 40 °C . The test results are shown in Table 1.

Table1. Test data of PC film

| Test temperature (°C) | O2 transmission rate (cm3 /m2 · 24h · 0.1MPa ) | O2 permeability coefficient ( 10-11 cm3 · cm/m2 · s · cmHg ) |

|---|---|---|

| 30 | 608.748 | 11.59 |

| 35 | 700.118 | 13.33 |

| 40 | 753.23 | 14.34 |

By fitting of data in the table we can get the oxygen permeability coefficient and oxygen transmission rate at 45 °C which are 16.04 × 10-11 cm3 · cm/m2 · s · cmHg and 842.85 cm3 /m2 · 24h · 0.1MPa respectively. The actual test data are 15.79 × 10-11 cm3 · cm/m2 · s · cmHg and 829.729 cm3 /m2 · 24h · 0.1Mpa respectively. Comparing the predicted data with the corresponding tested data the error between them is only 1.58% that is very ideal. Because the fitting function is not selective to materials, for the other films the usage is the same.

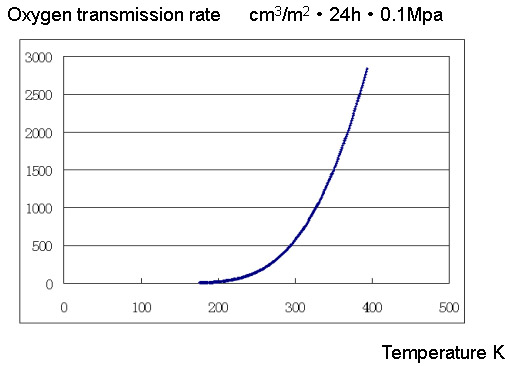

Furthermore, VAC-V1 can introduce the fitting data in a certain section of temperature range into a Excel file for convenient of the user to analyze and deal with the series of data. Herein the oxygen transmission rates (for example) at -100 °C ~120 °C (173K~393K) of this PC film, which are fitted from the 3 groups of test data, are introduced into an Excel file and a curve chart can be drawn as shown in figure 1“Curve of oxygen transmission rate- temperature for PC film”.

This VAC-V1 gas permeability test instrument can also perform fitting statistics of all the temperature points in the temperature limit. So users can easily know about the trend of barrier parameters with the temperature change in the entire temperature range.

4. Glass Transition Temperature T g of Polymer

4. Glass Transition Temperature T g of PolymerNoncrystalline polymers exist in two states: one is vitreous state in which state the molecular motion is fairly limited just like the molecules are frozen in the system; another is rubbery state in which state molecules can move a long distance so there exists no permanent pore space. The narrow temperature transition section in which polymer transits from the “vitreous state” at normal temperature to the “rubbery state” of different properties at high temperature is called as “Glass Transition Temperature(Tg )”. If T> Tg , the structure of polymer will has a creep deformation and be damaged. Hence we can see that the states of molecular motion above and below Tg are different, and there is an obvious turn near Tg in the curve of permeability coefficient-1/T.

5. Prospect

For the permeability of the usual inorganic gases, the fitting function of VAC-V1 is an effective way to obtain the values of P, D and S of special temperatures. With the development of science, there will have more and more methods to get the values of P, D and S of special temperatures and some empirical formulas will be further improved. What's more, the upgrade of testing technology will also provide a even more wider environmental test range. All of these will offer favorable term for acquisition of barrier parameters of non-standard tests at special temperatures.